HANDCRAFTED: HOW AN ONA BAG IS MADE

Behind the Scenes

ONA’s creative director Bryan Mochizuki shares a behind-the-scenes look at the quality and craft that goes into every piece in the core ONA collection.

| Since the very first ONA sample in 2009, we have worked with the same family-owned factory in the Dominican Republic. It’s where we still produce every messenger bag, backpack, and camera strap in our core collection. |

|

|

|

|

|

|

Producing in this way allows us a high level of craftsmanship, quality, continuity, and heritage. The woman who oversees all of the materials used in our bags has worked with our factory for over 30 years and can recall from memory details of every design since 2009. We handcraft our products in small runs of 100 or 250 pieces—instead of thousands at a time—which allows us a high attention to detail. And given the geographic proximity to our New York headquarters, we can work together closely and collaboratively. |

|

|

|

| Each bag is manufactured entirely—from uncut raw materials to finished product—within the four walls of our two-story factory. An individual bag can require up to 5 hours of total hands-on work to produce, with up to 15 individuals directly involved and at least 3 quality checkpoints. And as all of our sample-making happens in the same building, the team that helps us develop each new style can train and work directly with the craftspeople who ultimately produce them. |

|

|

|

|

First, on the ground floor of the factory, all of the raw materials—full-grain leather, 14oz waxed canvas, solid brass hardware—are assessed, cut, and prepared for assembly through a number of methods depending on the style. The materials are then carefully sorted and organized until they’re ready to be produced. |

|

|

|

|

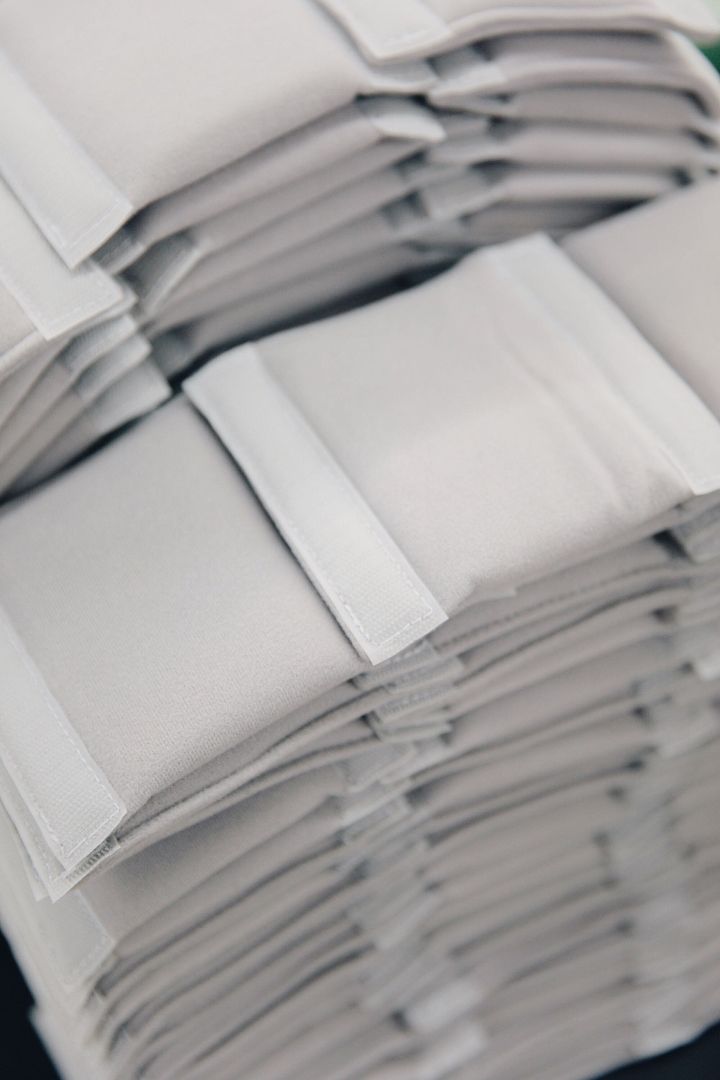

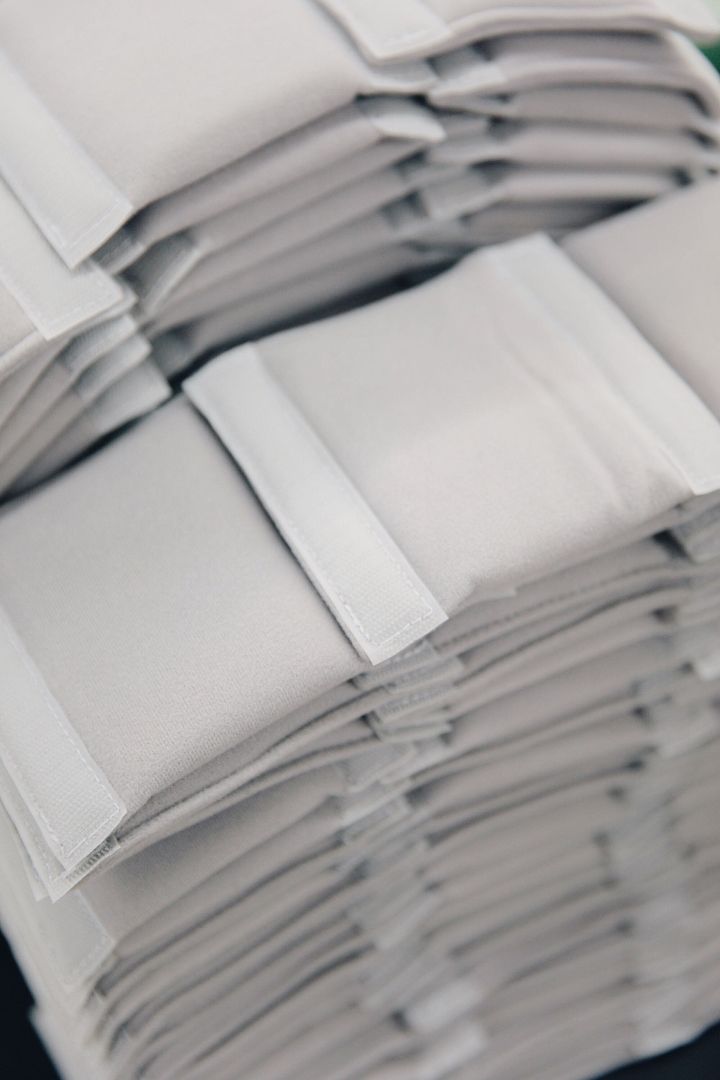

Upstairs, each bag comes to life—gradually, deliberately—through a number of individually-manned stations, each dedicated to specific pieces of the process: stitching large panels together, attaching hardware, fine details, edge-painting. Finally each bag is given one last check for quality before being placed in a dust-bag and packaged.

|

|

|

|

|

We are proud to serve a global community of photographers and storytellers, who value quality, craft, and process in their work. We seek to mirror that in every good we produce, through the people, technique, and heritage that we know goes into the final product. |

|

|

Handcrafted with water-resistant waxed canvas and detailed with full-grain leather accents, the ONA Bolton Street Backpack is expertly designed to protect your gear while making it available in an instant with two convenient side-access pockets. Made with closed-cell foam, the main interior compartment is fully customizable and can carry a camera and up to six lenses. A back pocket protects up to a 13-inch laptop, with pockets for a smartphone, lens cap, batteries and memory cards while a front pocket can be used for small everyday essentials.

|

Exterior dimensions

|

16.5"L X 13.5"W X 8"D

|

|

Interior dimensions

|

15.5"L X 12.5"W X 6.5"D

|

|

Weight

|

1.4 kgs

|

ONA Bolton Street Backpack